The Aston Martin Valkyrie is a hyper-car that was developed in collaboration with Red Bull Advanced Technologies and Cosworth. The car is the brainchild of Adrian Newey, who is one of the most accomplished car designers and aerodynamicists in Formula 1. The car is powered by a hybrid powertrain, which consists of a naturally-aspirated V12 engine and an electric motor. The Valkyrie is one of the most powerful and expensive cars, with a price tag of $3.9 million and only 150 units to be produced.

“It’s a car that’s perhaps more targeted and focused than other cars have been. We didn’t do any benchmarking against potential competitor cars because we wanted to try and establish a new genre of car that was more track biased than other road cars have been, while still making it usable on the road”

Adrian Newey

valkyrie Technical Specifications

Valkyrie has an all-composite monocoque structure to reduce weight, which was one of the main goal of the designer; in fact, at kerb weight, it has a power-to-weight ratio of 1:1

| Parameter | Specs |

| Weight | 1355 kg |

| Length | 4.50 m |

| Wheel Base | 2.77 m |

| Acceleration | 0 to 60 mph in 2.5 seconds |

| Top Speed | 200 mph or 322 kph |

| RPM Limit | 1000 RPM |

| Power | 1000 BHP @ 10,500 RPM |

Power Train & Crossworth Engine

Valkyrie has a hybrid powerplant comprised of an electric motor and a naturally aspirated engine. Engine: The main driving element is a 6.5L V12 capable of producing 1000 BHP. The engine was specifically developed for this project by Crossworth. Although engine design is based on existing technology, it is a masterpiece in itself due to stringent design requirements (Aston Martin restricts the weight budget to 200kg) and emission regulation. Specifications are as below:

| Parameter | Specs |

| Displacement | 6500 CC |

| Configuration | V-12 65deg |

| Max. Operating RPM | 10,500 |

| Peak Torque | 900 Nm |

| Power | 1000 BHP @ 10,500 RPM |

| RPM Limit | 1000 RPM |

| Power | 1000 BHP @ 10,500 RPM |

Therefore, the resulting engine has a maximum operating RPM of 10,500, which is almost twice as much compared to normal road cars. Crankshafts and pistons are machined through single metal blocks to reduce the component count and weight while maintaining the same load-bearing capacity. The engine is claimed to have a life of 100,000 km, which is quite high for a high-performance engine. The configuration is a 65-degree V with separate plenums on each side. Port injection is used to comply with Euro-6 emission standards while keeping a minimal component count.

The engine and gearbox are designed to be load-bearing structural elements. It means the engine is not only producing power, but it is also acting as a truss in the integration of the vehicle’s chassis, suspension, and gearbox. The main challenge is reducing the weight while making the engine block strong enough to bear asymmetrical torsion loads due to the load imbalance of the front and rear suspension.

Gear Box

The gearbox was developed by Ricardo, and it is a seven-speed single clutch twin barrel. All the gears are forward shift; the car uses an electric motor for reverse drive.

Electric Power

The car has KERS to charge the battery, and the battery motor combination serves the following functionality:

- Start the Car

- Reverse Gear

- Slow-speed drive (below 10 mph)

- 160 HP power (torque 280 Nm)

Suspension

The Valkyrie utilizes a double wishbone, pushrod suspension configuration at both the front and rear axles. This type of suspension offers several advantages that enable this car to provide precise handling, adjustable-height active-suspension and electronically adjustable dampers. All this is performed

Aerodynamic Analysis

Front Section

The front section has a single element; the front wing comprises multiple elements. The last two elements are shorter to induce the vortex flow, which will enhance the flow mixing between the high-pressure (upper surface) and low-pressure (lower surface) air on the front wing element. The flow deflectors in front of the wheels divert the air away from the wheels. The tip is curled outside to enhance vortex so that pressure in front of the wheel is relaxed and the effect of wheel wells is minimal.

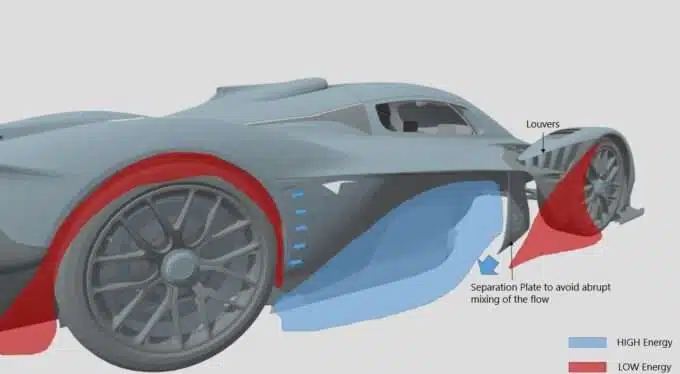

Floor and Side Section

The floor consists of two large venturi tunnels to maximize the downforce. For this purpose, a larger scoop of air is drawn from the front section and a major portion of it is routed under the floor. The side section shares similarities with the open-wheel race car. The flow at side-channels serves two purposes: first, they relieve some pressure on the underfloor by imposing suction, and secondly the flow at side walls eases out the flow separation on the front and rear wheel wells. Moreover, louvers are placed over the front wheel wells to ease some pressure.

Rear Section and The Diffuser

The car has a wide diffuser at the rear like other sports cars, but it is different from anything seen before. It shares similarities with Red Bull Racing’s RB-19 Formula 1 car. The walls of the diffuser are extended outside to channelize the flow outside the region of influence of rotating wheels. This will prevent the high-pressure flow at the rear end from creeping into the diffuser section.

On track performance of the car is nothing compared to other road legal cars. It provides drivers with real Formula 1 experience. However, the car has yet to taste racing experience. Valkyrie will participate in Le Mans 2025.